Microsoft Dynamics 365 Supply Chain Management

Modernize supply chain operations – optimize visibility, planning, procurement and fulfilment

Manufacturing and distribution companies in the supply chain today face a range of challenges that impact their operations and profitability. Rising materials and labor costs are squeezing margins. Balancing inventory management and demand planning remains a challenge, as businesses navigate the trade-off between just-in-time inventory practices and the need for buffer stock to handle supply chain volatility and seasonal demand.

While regulatory compliance adds another layer of complexity with evolving environmental, safety and trade regulations. Consumer expectations are also shifting, with growing demand for faster delivery, product customization and sustainable practices, forcing businesses to become more agile.

Using innovative technology in cloud-based ERP software, such as automation and AI to move from reactive to proactive operations is key.

What is Dynamics 365 Supply Chain Management?

Microsoft Dynamics 365 Supply Chain Management (built on Microsoft Dynamics 365 Finance and Operations) is an enterprise resource planning (ERP) solution designed to help businesses build an agile, connected and resilient supply chain.

Streamline planning, production, stock, warehouse and transportation to maximize operational efficiency, product quality and profitability using predictive insights from AI and the Internet of Things (IoT).

BENEFITS – Microsoft Dynamics 365 Supply Chain Management

Optimize Supply Chain Operations

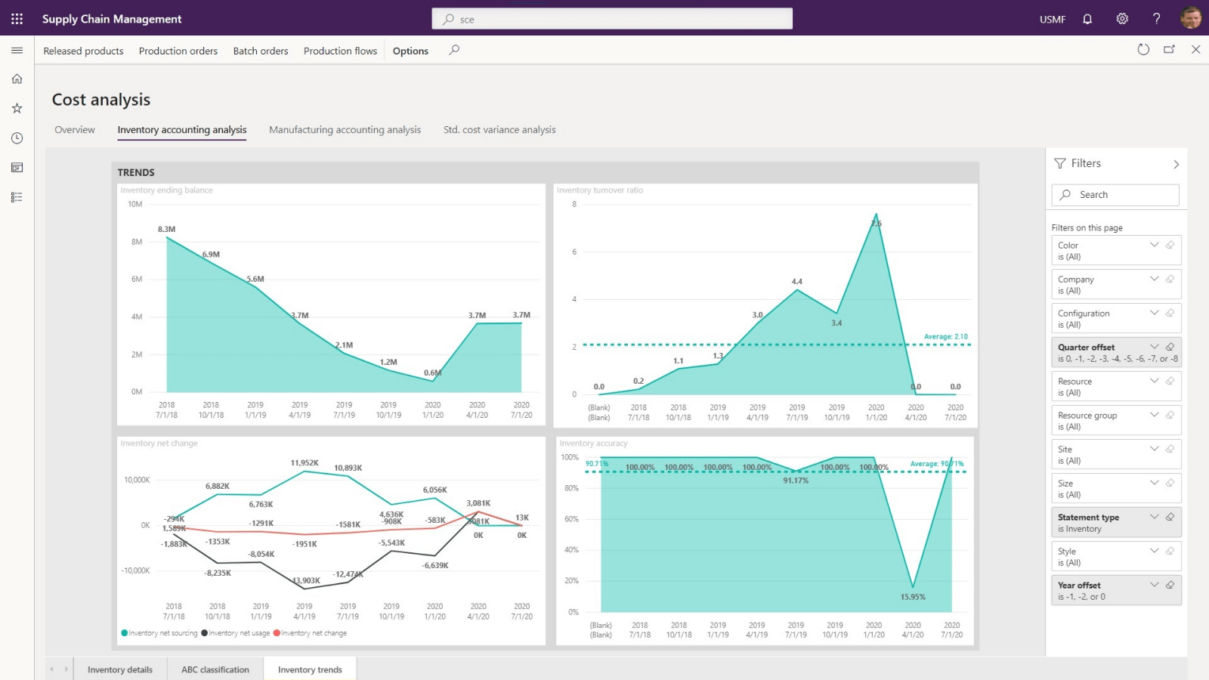

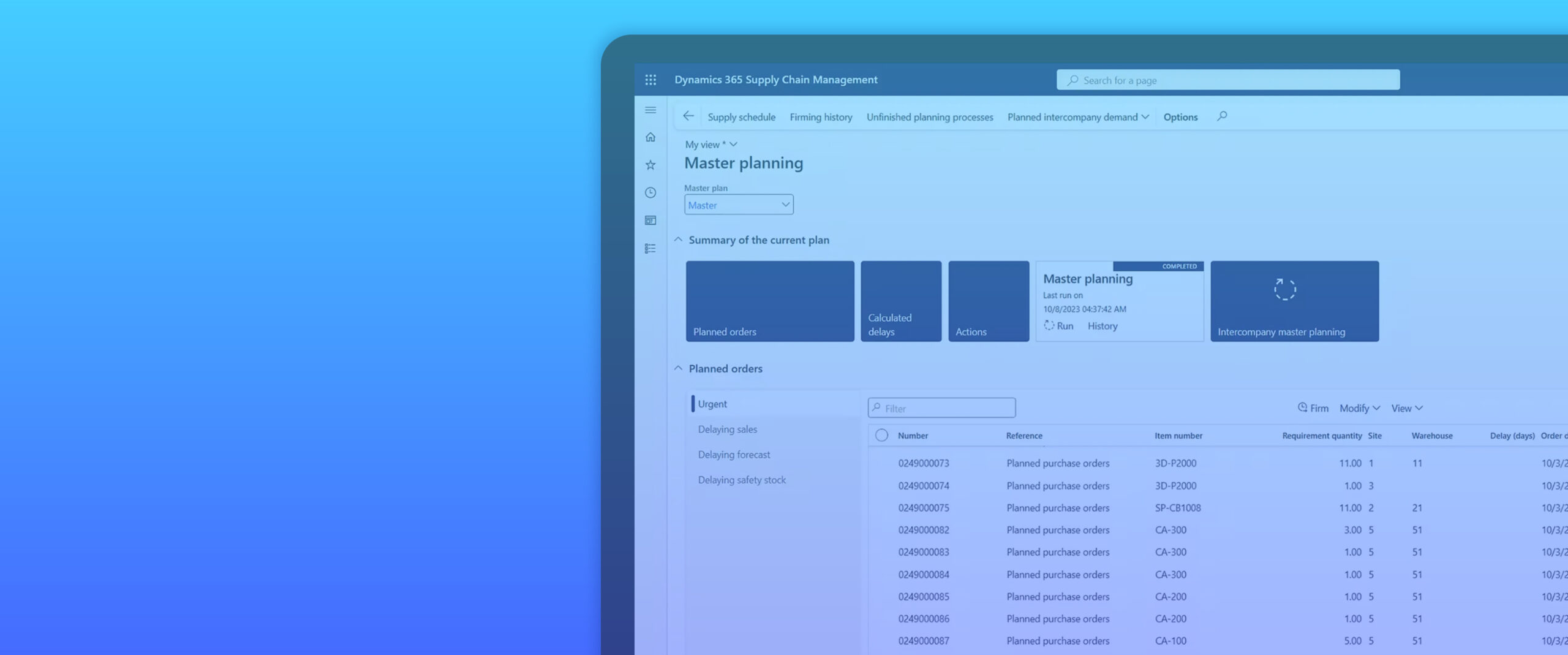

Improve production planning, inventory management, warehouse operations, logistics and procurement through supply chain automation, AI-driven insights and real-time data tracking.

Scalable and Flexible ERP Technology

A cloud-based supply chain solution that scales with business growth with customizable workflows and integrations with Microsoft Power Platform, Microsoft Azure and Microsoft 365.

CAPABILITIES – Microsoft Dynamics 365 Supply Chain Management

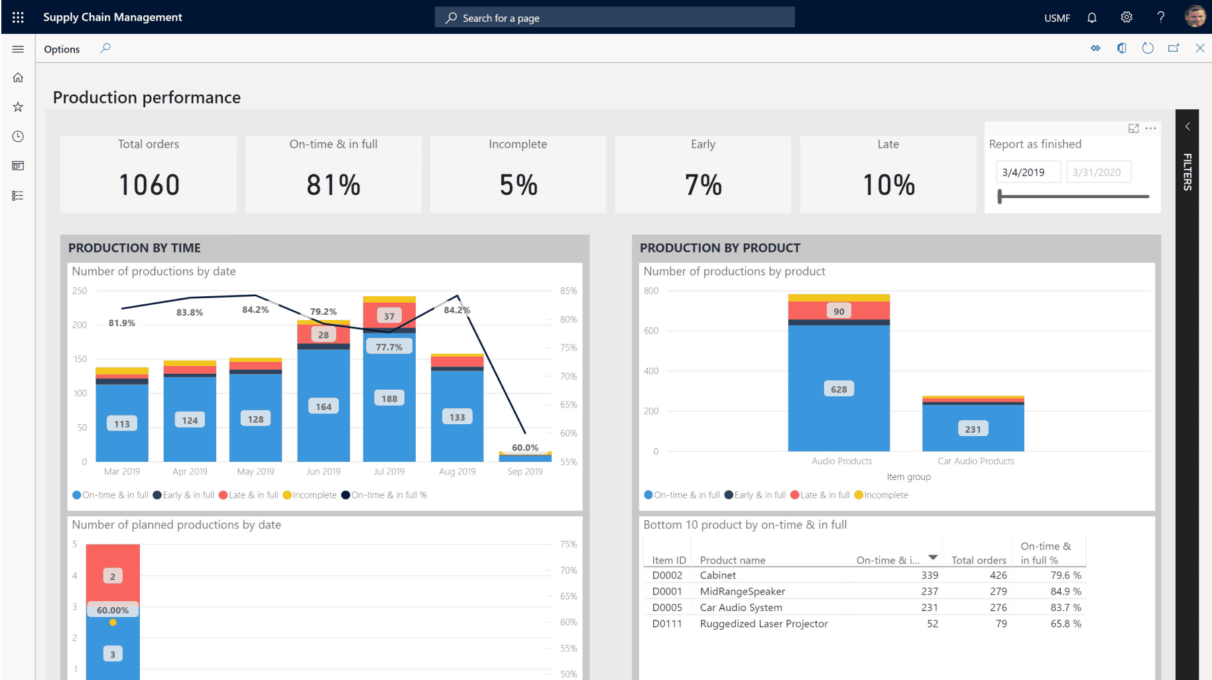

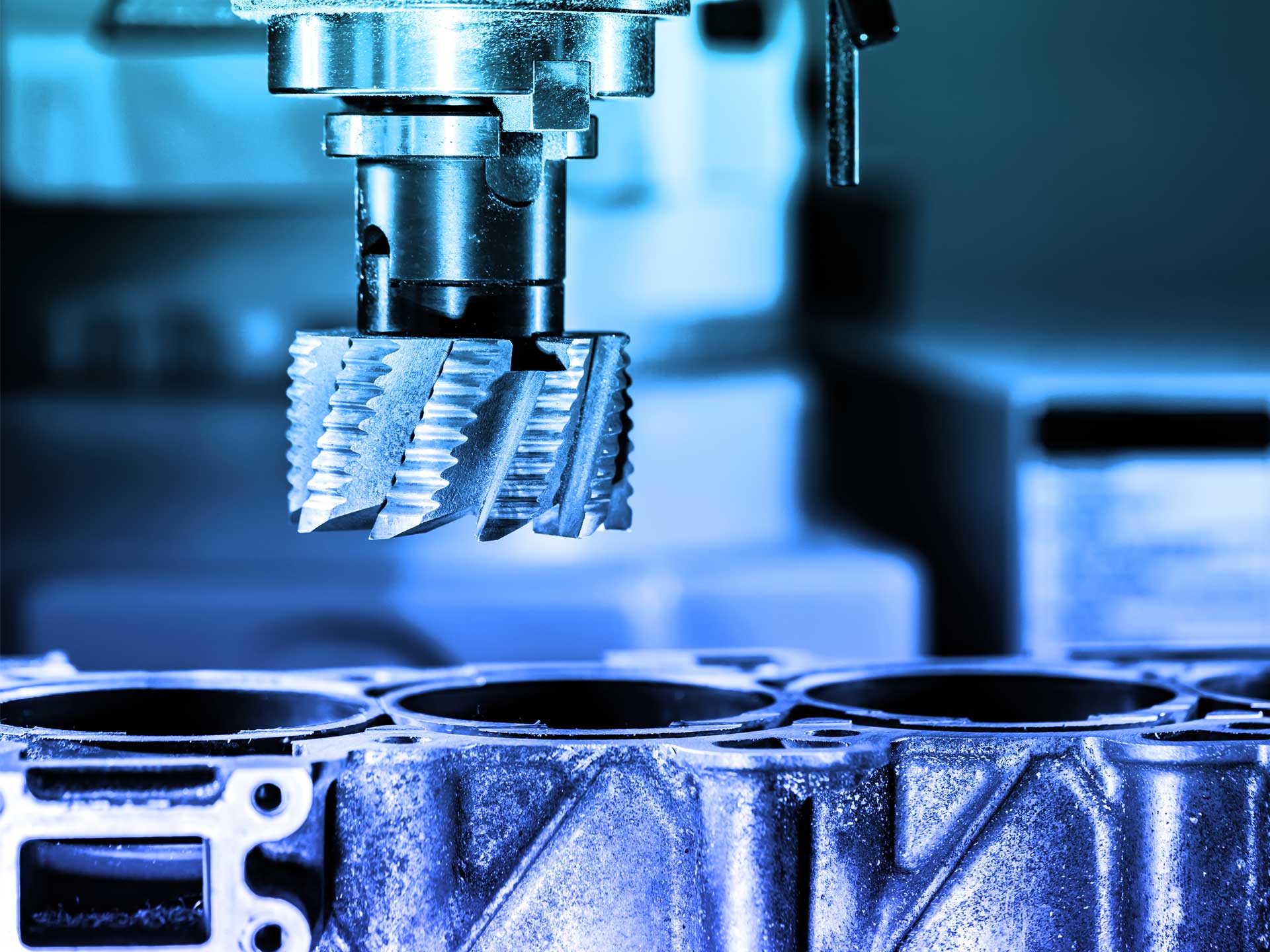

Intelligent Manufacturing Operations

Automate supply chain management processes with the IoT integration, AI, machine learning and mixed reality to optimize people, workflows and equipment.

Optimize production – proactively managing shopfloor and equipment operations with a real-time view of your entire production and stock. IoT-enabled sensors can alert you to delays or potential issues, allowing quick responses.

Supports lean manufacturing and just-in-time (JIT) production to reduce waste.

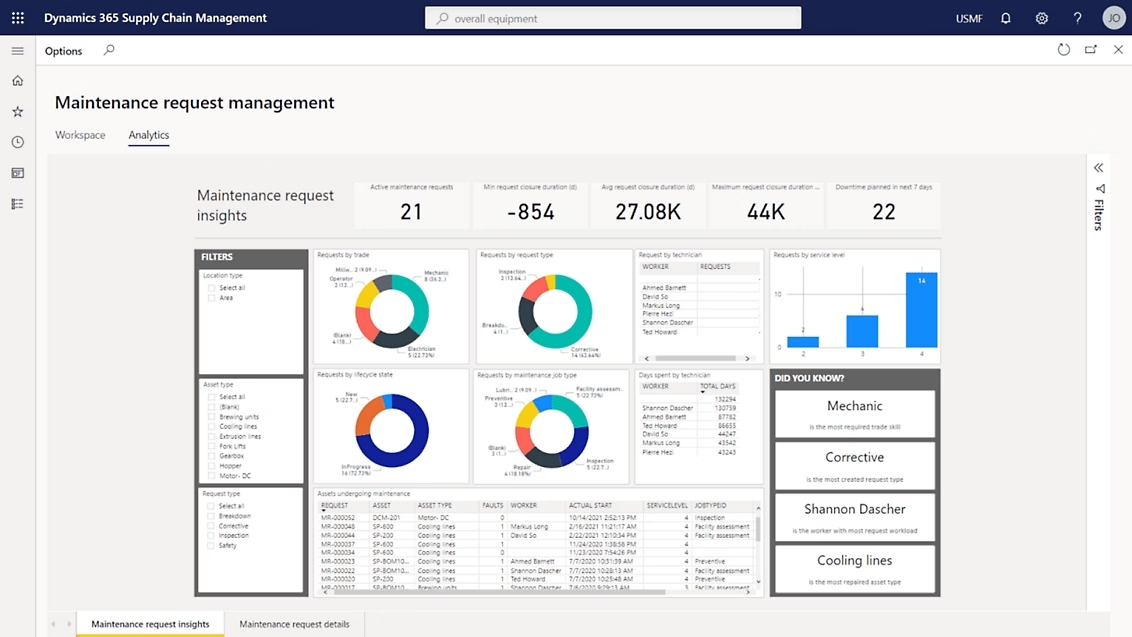

Improves efficiency with IoT and AI-powered predictive maintenance.

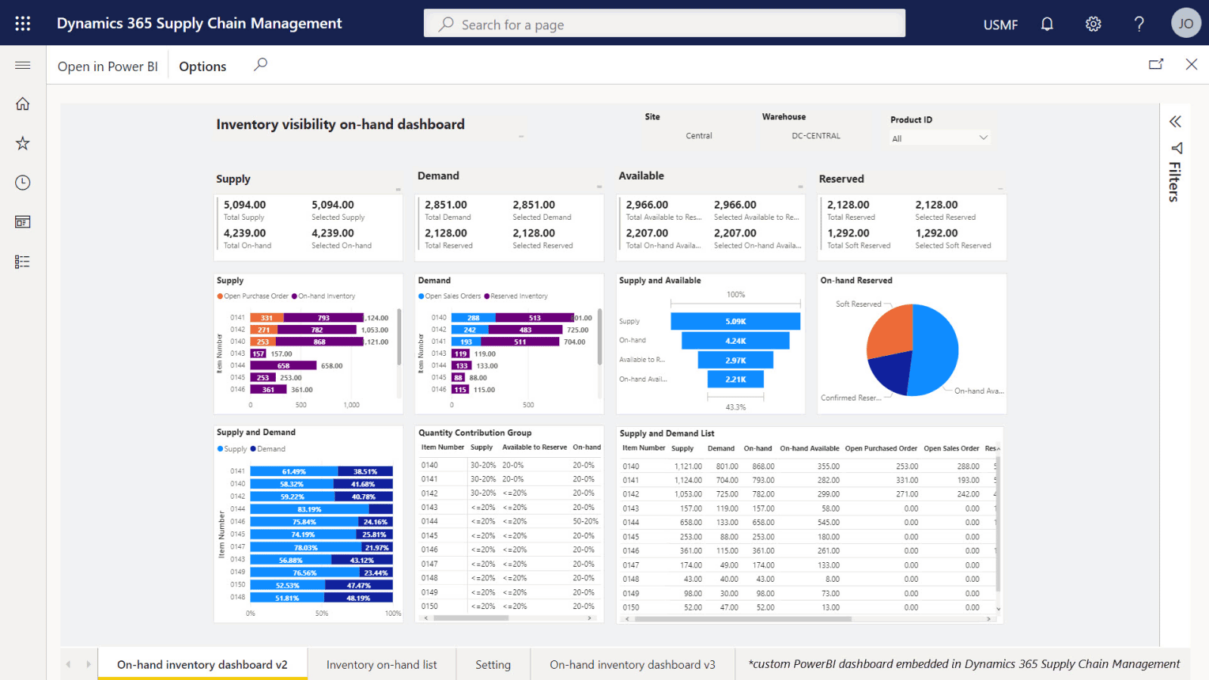

Modernize Warehouse Management

Gain full visibility of your stock and receiving, picking and shipping operations and create heatmaps of your warehouse processes. Automate and scale your warehouse management to optimize use of space, from stockrooms to distribution centers.

Optimize inventory levels with automated replenishment and real-time tracking. Reduce stock discrepancies with barcode scanning and RFID integration.

Simplify multi-warehouse management with smooth coordination between different locations for fulfilment optimization.

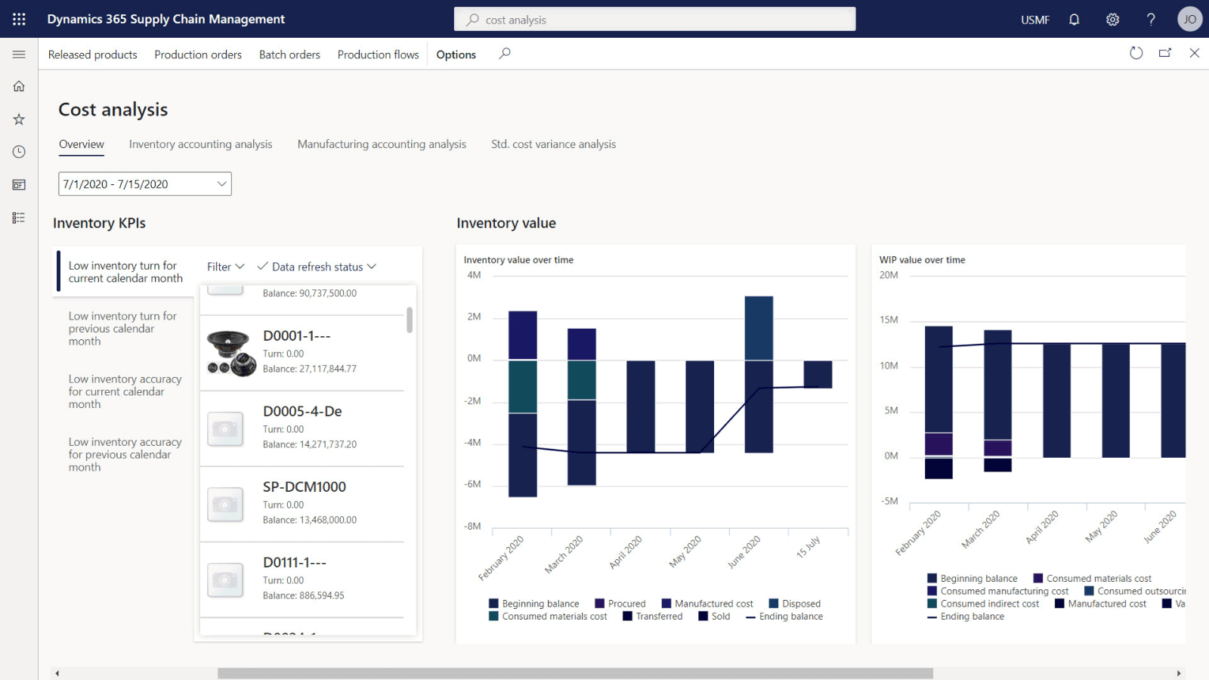

Enhanced Supply Chain Visibility

Integrate sales and purchasing with logistics, stock, production, warehouse and transportation management for real-time insights

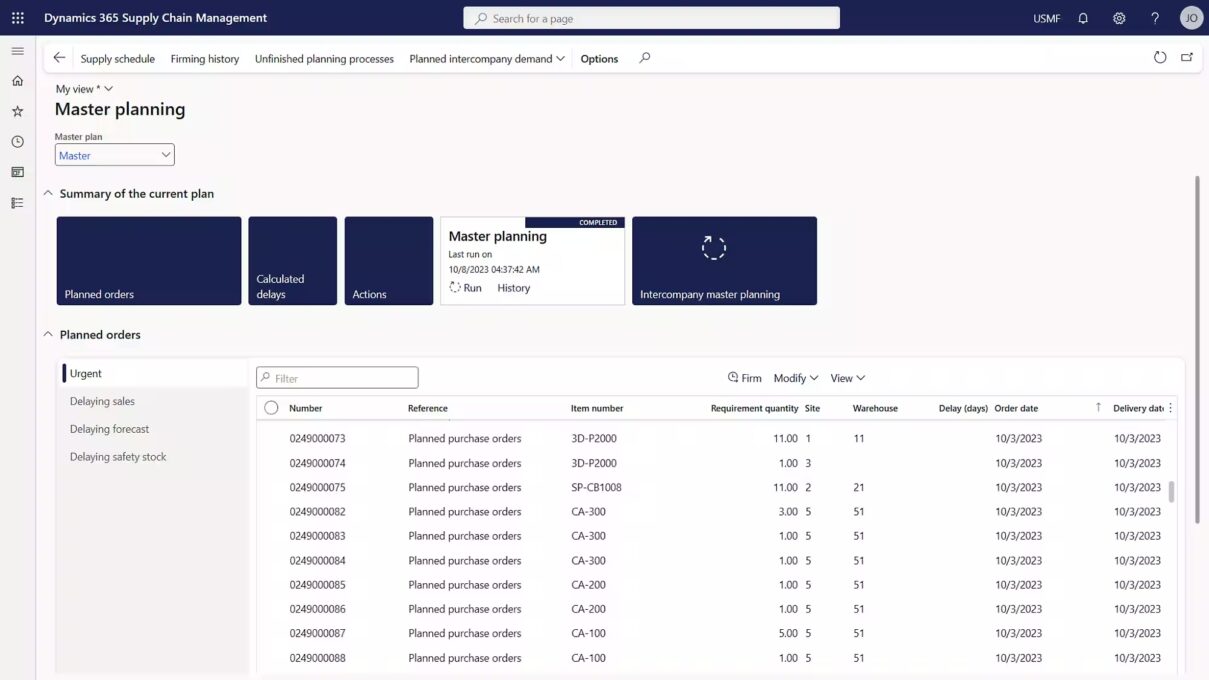

Enable demand-driven production by integrating sales and supply chain data for

real-time supply chain planning and data-driven decision making with Microsoft Power BI and embedded analytics.

Adapt to changing customer demand, material availability and capacity constraints across multiple sites and warehouses.

Track the flow of goods from procurement through to delivery, for greater control and proactive problem-solving.

Advanced Procurement and Vendor Management

Streamline purchasing, optimize supplier relationships and ensure cost-effective procurement strategies with robust procurement and vendor collaboration tools.

Automate purchase order processing, approval workflows and AI-driven supplier selection.

Enhance supplier relationships with integrated communication, vendor collaboration portal and performance tracking on KPIs such as on-time delivery, quality and pricing.

Gain insights into procurement spending trends to negotiate better contracts and pricing with spend analysis tools.

Optimize Logistics and Transportation

Improve delivery timelines by optimizing route planning and dynamic adjustments, use AI-powered route optimization which analyzes historical data, real-time traffic conditions, weather forecasts and delivery windows to suggest the most efficient routes for transportation.

Track shipments end to end, from the warehouse to the final destination, giving you full visibility into the location and status of goods in transit, with automatic notifications of status to you and the customer.

Integrate with third-party logistics (3PL) providers such as UPS and FedEx, for automated supplier communication with real-time updates on delivery status, delays and estimated delivery times.

Reduce costs with AI-driven freight and transport management for a digital supply chain.

FEATURES – Microsoft Dynamics 365 Supply Chain Management

AI and Copilot in Microsoft Dynamics 365 Supply Chain Management

The Microsoft Dynamics 365 Supply Chain Management system leverages AI-powered insights and Copilot with automation to enhance decision-making, improve supply chain efficiency and streamline operations with AI. These features use machine learning (ML), predictive analytics and automation to help businesses optimize inventory, demand forecasting, transportation and warehouse operations.

Copilot to Streamline the Supply Chain

Automated alerts for supply chain disruptions (delays, stockouts, logistics issues).

Proactive risk assessment with alternative supplier and routing recommendations.

Conversational AI helps users quickly retrieve order, inventory or supplier details.

Copilot for Sustainability

AI-powered carbon emission tracking for logistics and supply chain.

Suggests eco-friendly transportation and material sourcing.

Automates sustainability reporting for compliance (EU Green Deal, ESG standards).

AI-Powered Predictions

Uses historical data, market trends and external factors to predict demand.

Optimizes stock levels, reducing overstocking and stockouts.

AI and IoT sensors monitor machine health and performance for predictive maintenance.

AI for Inventory

AI suggests optimal reorder points based on sales trends and lead times.

Automates stock replenishment without manual intervention.

Improves cash flow by reducing excess inventory holding costs. Dynamically allocates storage space.

AI Analytics for Procurement

Tracks supplier on-time delivery, quality and cost efficiency.

Recommends the best suppliers based on AI-driven scoring models.

Identifies potential disruptions before they impact production.

AI for Warehouse & Logistics

AI-driven route and warehouse optimization to reduce transit time, fuel costs, optimal picking and packing routes

Identifies cheapest and fastest shipping methods.

Predicts potential shipping delays, warehouse bottlenecks and suggests alternatives.

Prodware Vertical Solutions and Accelerators for Supply Chain Management

Why choose Prodware?

We are ScoreFact certified on Microsoft Dynamics 365 Supply Chain Management.

Prodware has worked within the manufacturing and distribution sectors for more than twenty years. In addition to our strong customer base over multiple countries we have developed sector-specific solutions and accelerators to complement Microsoft technology to drive supply chain management optimization.